This is my attempt to demonstrate, to myself as much as anybody, that a decent guitar can be built with locally available woods. Now, that might seem odd coming from a person who probably has more wild and exotic wood to choose from than anybody short of Randy B, but I gotta do it anyway

For tops, this is not a problem because I almost always use my own local white spruce, even though I have all those weird versions of sitka plus Italian and Engelmann, too. But for this one, I chose to not take the easy route and am using black spruce, Picea mariana. This is the "other" local spruce here that is probably about the best there is. It has the longest fibers of any spruce and is incredibaly strong. About the same density as red spruce. So why don't we see more of it? Well, the main reason is that it rarely gets much bigger than about 12" in diameter, and 16" is a huge tree. So what I needed to do is make a 4-piece top, which will be obvious s we go along..

After I glued it up, which I actually did several years ago, my first step was to put in the rosette. One thing that does not grow locally is a dark colored wood. So I had to really scrounge to get some contrasting woods to use for trim and such. I ended up with a palette made up of butternut for the dark, maple for the light, and sumac for the basic pizazz. Ya sumac. it just grows as a very small tree, but has this almost metallic golden olive wood, unlike anything else I have ever seen.

So here is my rosette glued in. Just a simple double ring with the wide one having a sumac center. I will also use that wood for the end graft and bindings. After I glue it in, I cut the sound hole. Notice the nice rays.

Here that is. What you don't see is that first I added a cross grain spruce patch on the inside to double up the thickness immediately around the sound hole, inside the soundhole braces. This wood does have a scattering of tiny 'pecky" spots, but it does not seem to affect the tone. I am using it because it is the only black spruce I have at this time and i want to try it.

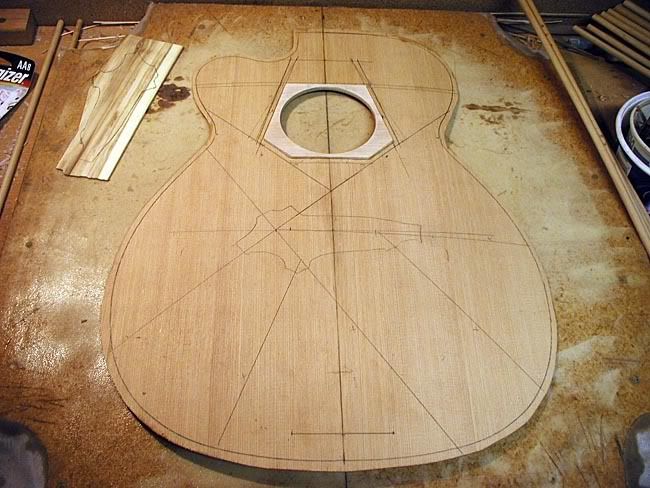

Here is the top ready to brace.

You can see the crossgrain patch in this photo, and I have drawn on the bracing pattern. I have a whole topic on my bracing pattern, so I will run through this rather quickly. Note my bridge plate ready to cut out at the upper left. This is of black locust, which I will also be using for the bridge, fingerboard, and peghead overlay.

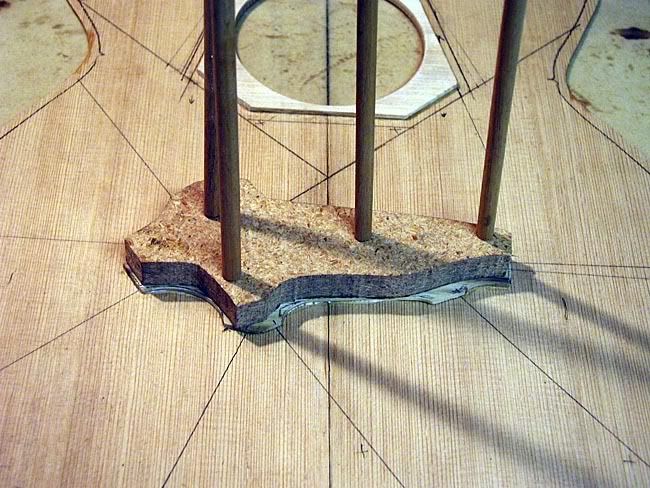

The first thing to get glued in is my odd shaped bridge plate

Here it is clamped with a shaped caul.

A major component of my bracing pattern is a series of three curved braces. These are made from two laminations of bent 1/8" thick spruce. Here is one being sanded to the top radius.

And here are the 3 of them being glued in.

They are then carved to a triangular cross section and sanded smooth. I have now gotten smarter and carve and sand these braces before I glue them in.

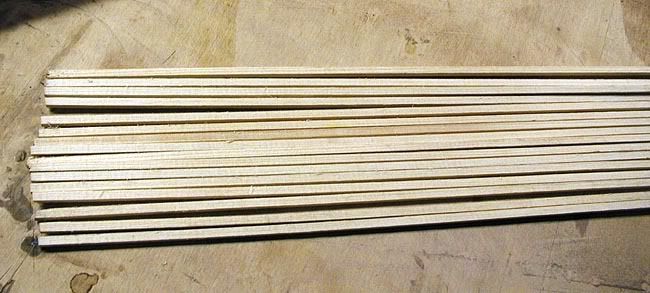

I make my brace stock from split billets of straight grain white spruce sapwood.

You can see the check in the surface of this billet that shows the run of the grain

I am now laminating most of my braces as they are glued in with the top in the radius dish

I cut the split brace stock into 3/16" wide by 5/32" thick strips to do the laminations. I glue up a total of 5 layers.

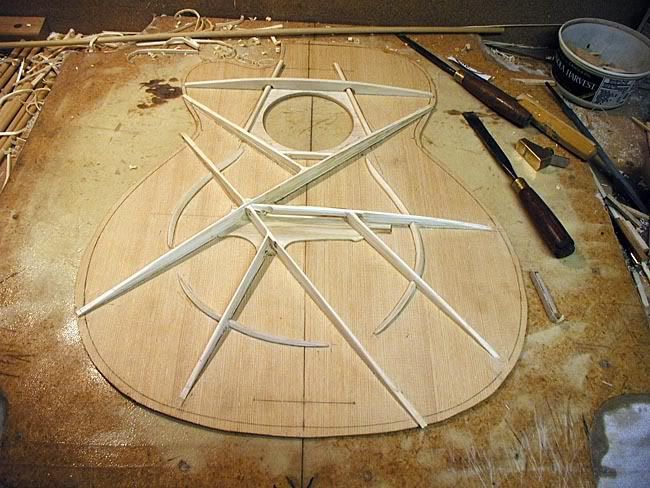

This series of photos shows stages of the glue up. At the offset "X", alternating layers cross over different directions to lock the joint together. All other joints are just butted.

The braces on the upper end of the soundboard are not laminated. This part of the bracing arrangement is designed to accomodate my adjustable neck.

Note the gap left under the brace that is under the bridge saddle location. This is to allow a space for a stick-on pickup such as a B-Band. After all the gluing is finished the braces are profiled with a specially ground router bit to a tapered, almost knife edge cross section.

Here is the bit I use for that and the final result on a scrap sample.

Here are the braces roughly carved, and...

here is everything sanded and ready to go.

I will take a break now and will pick up with the neck and body tomorrow.