Well, I have not been slacking on the building....just the documentation. I will attempt to catch up a bit.

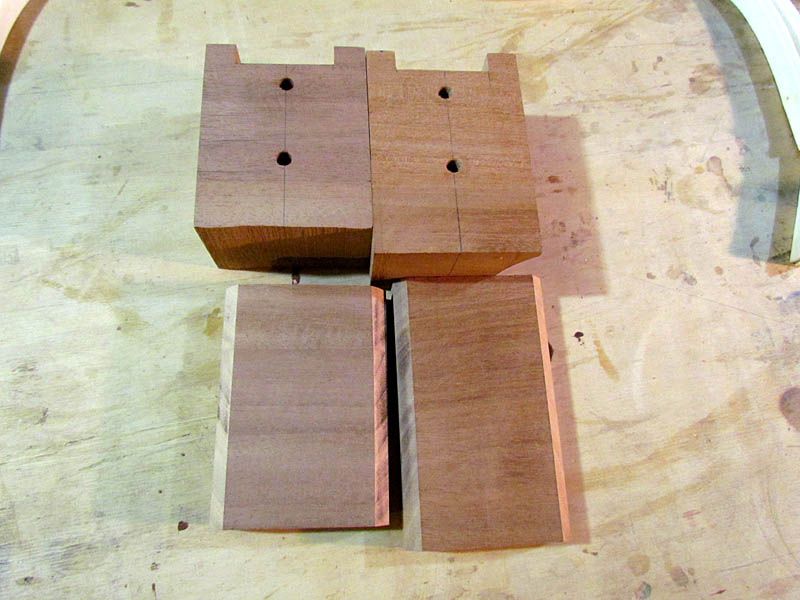

Since I build on a work board without a mold, my first step in putting the box together is to glue the end blocks to the top

Notice the small alignment blocks glued to the top. These keep the blocks square with the guitar body during clamping. They are carved off after the glue is dry.

Next, I test fit the sides and mark the exact length and the end points of the linings (no photo)

After trimming the sides to length, I test fit the linings to the sides and trim them to length

Then I glue the linings to the sides

This is the top lining. I did the same with the back linings. In the past, I have done the back linings after the sides were glued to the top. With the stiffer thermally modified sides, I found it worked better to do both linings up front.

I also glued the side braces before gluing the sides to the top

With everything glued on the sides, they are extremely ridgid, so it is quite easy to glue on one at a time. Here is the first side being glued on

And the second side

The next step is to join and brace the back. I will be using my regular laminated double X, and I want to do it with thermally modified brace wood. So, I just wrapped a bundle of my regular mahogany bracing strips in aluminum foil and baked them at 380F for 45 minutes. They did get up to a bit over 400F for about 10 minutes.

They came out fine, with a nice musical tone. Note the uncooked strips in the back for comparison.

And here is the joined and thicknessed back

Next, I will show the back bracing.

G