OK, what I want for the top purflings is 3 lines, starting at the binding going inward, red/holly/black. Now handling this many separate veneer lines while instaling the binding can be a pain in the pa-toot, I know, I have done it. Gluing up that many lines and then trying to bend the whole thing is also a pain.

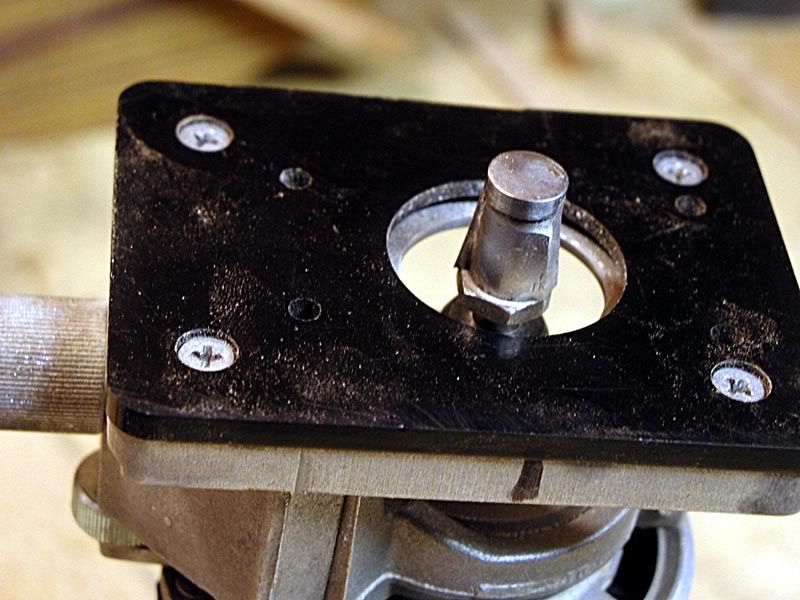

So I thought, why not glue up a veneer sandwich, tape it to the side bending form and let it dry. Then saw already bent purflings off the edge

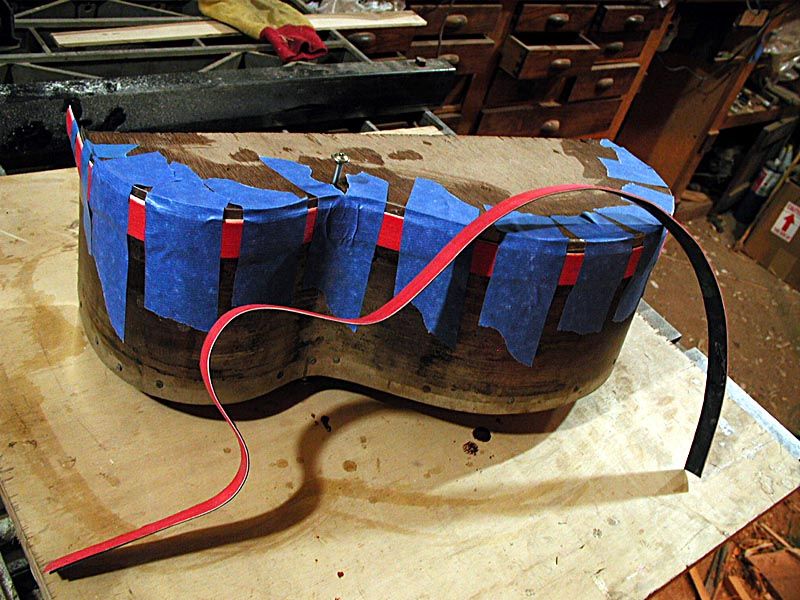

So I cut two strips of each color (a set for the cutaway and non-cutaway sides), glued and stacked them and bent them around the side forms. Taped heavily and let them dry for an overnight. Here is one on the form and one taken off

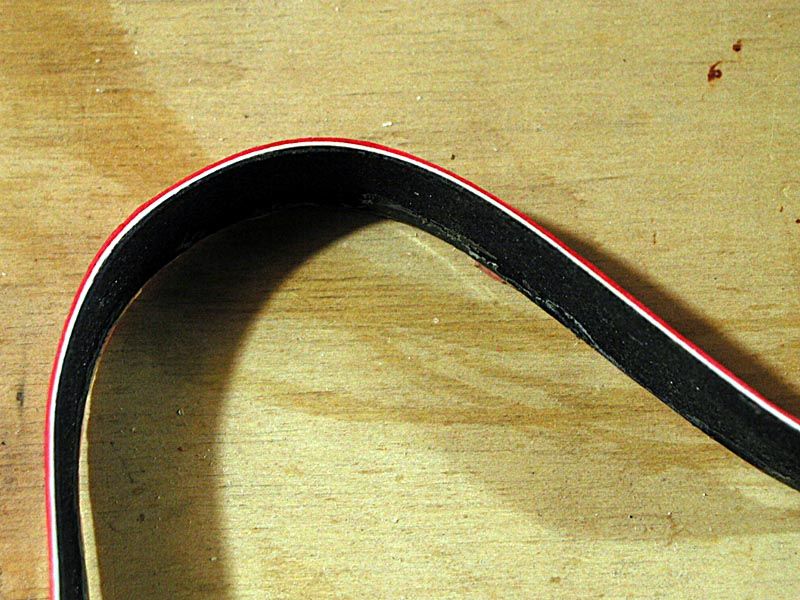

And here is a closeup

One thing that is a must-do with this is after you have the glued veneer stacked up, spritz both faces with water and wipe it over the surface...keeps the outer layers of veneer from curling.

Now there are a few slight irregularities in these, but I intentionally glued them with plain wood glue. That way they will wet up a bit when being glued on with the bindings, and the bindings will form a gluing caul to even them out.

G