Curly Maple Cutaway for Debbie

Posted: Sat Aug 30, 2008 11:30 am

When I took my curly maple build in to work there was lady there who liked it so much she commissioned me to build her a guitar. Since she didn't play I tried to talk her out of it, but she said she understood the cost and was planning to learn how to play. And besides she hopes to have an early Feissli for when I become famous

She likes the abalone and likes the idea of a soundport, so more bling and a few extra holes here and there.

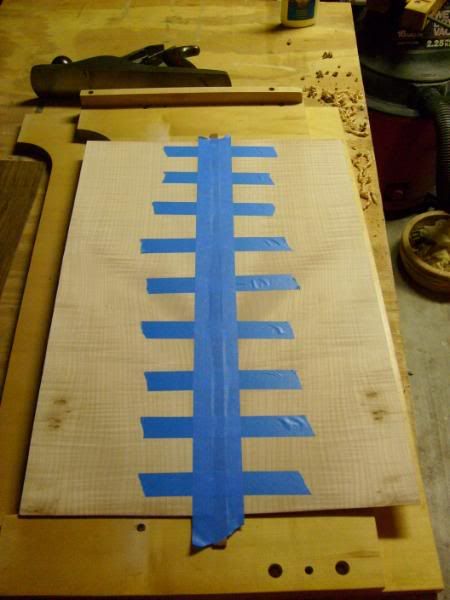

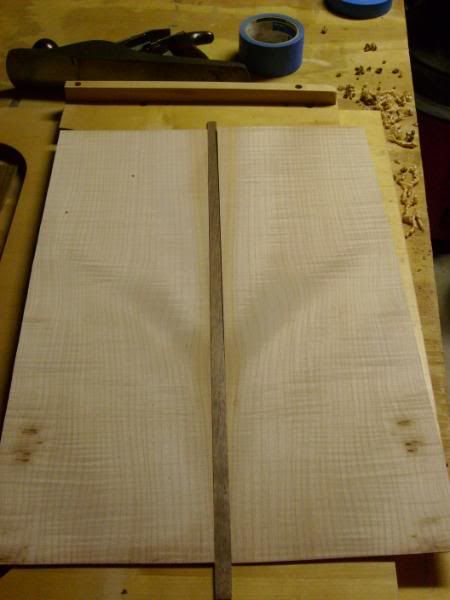

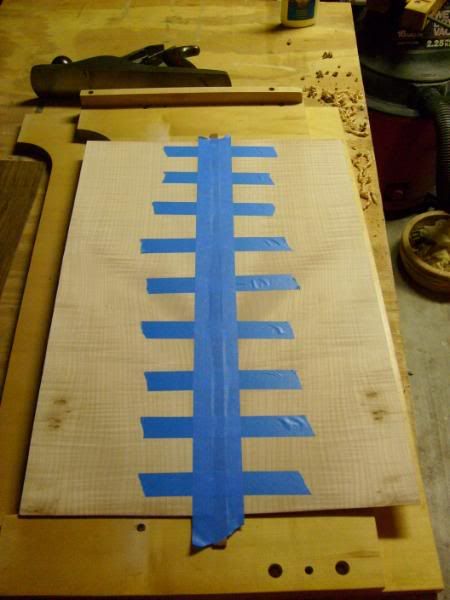

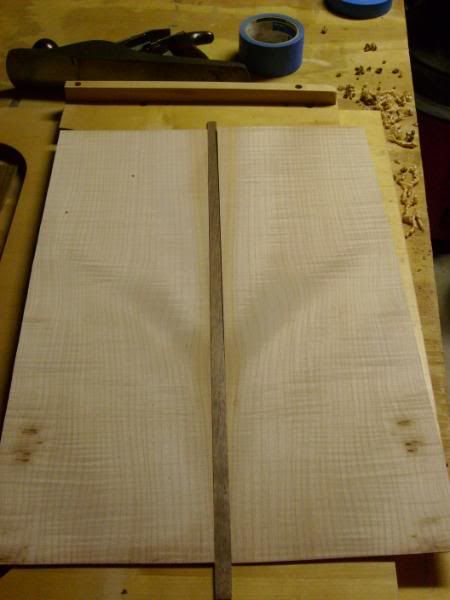

To start with the back I used the tape method I learned from Steve.

The sides were from the same billet as the previous build which was almost too thin so I added a strip of walnut.

I also joined the spruce top but didn't take a picture of it.

Ran them both through Eben's drum sander.

I cut the neck pieces out of a plank of flatsawn curly maple and a center strip from walnut.

I don't like to have to match up the laminates in the stacked heal or headstock, so I cut the whole shape out.

Bending:

A couple of shots of my bending form to see how I did the cutaway.

I cut out the form with no cutaway first, and then cut out the cutaway and kept the offcut. I had cut them out before joining the boards so the offcuts got joined separately. I added some plywood sides to hold them on and found that the cutaway fit snugly enough I didn't need any pins to hold it in place.

Lunch is calling so more later.

Raymond

She likes the abalone and likes the idea of a soundport, so more bling and a few extra holes here and there.

To start with the back I used the tape method I learned from Steve.

The sides were from the same billet as the previous build which was almost too thin so I added a strip of walnut.

I also joined the spruce top but didn't take a picture of it.

Ran them both through Eben's drum sander.

I cut the neck pieces out of a plank of flatsawn curly maple and a center strip from walnut.

I don't like to have to match up the laminates in the stacked heal or headstock, so I cut the whole shape out.

Bending:

A couple of shots of my bending form to see how I did the cutaway.

I cut out the form with no cutaway first, and then cut out the cutaway and kept the offcut. I had cut them out before joining the boards so the offcuts got joined separately. I added some plywood sides to hold them on and found that the cutaway fit snugly enough I didn't need any pins to hold it in place.

Lunch is calling so more later.

Raymond